Gas Detectors And Gas Analyzers: Ensuring Safety And Precision In Industrial Environments

Introduction

Working in environments with heavy-duty gases, chemicals, or restrained spaces can be dangerous without specific monitoring. Many professionals face challenges in detecting gas leaks, venomous emissions, or atomic number 8 deficiencies before they step up into dodgy situations. The potentiality for accidents, wellness hazards, and costly downtime makes effective gas monitoring a vital come to for industries and workplaces alike.

Thankfully, modern engineering offers reliable and competent solutions. Gas detectors and gas analyzers supply real-time monitoring of vesicatory gases, allowing proactive safety measures and regulative submission. These not only safe-conduct personnel office but also optimize industrial processes for and productiveness.

Understanding Gas Detectors

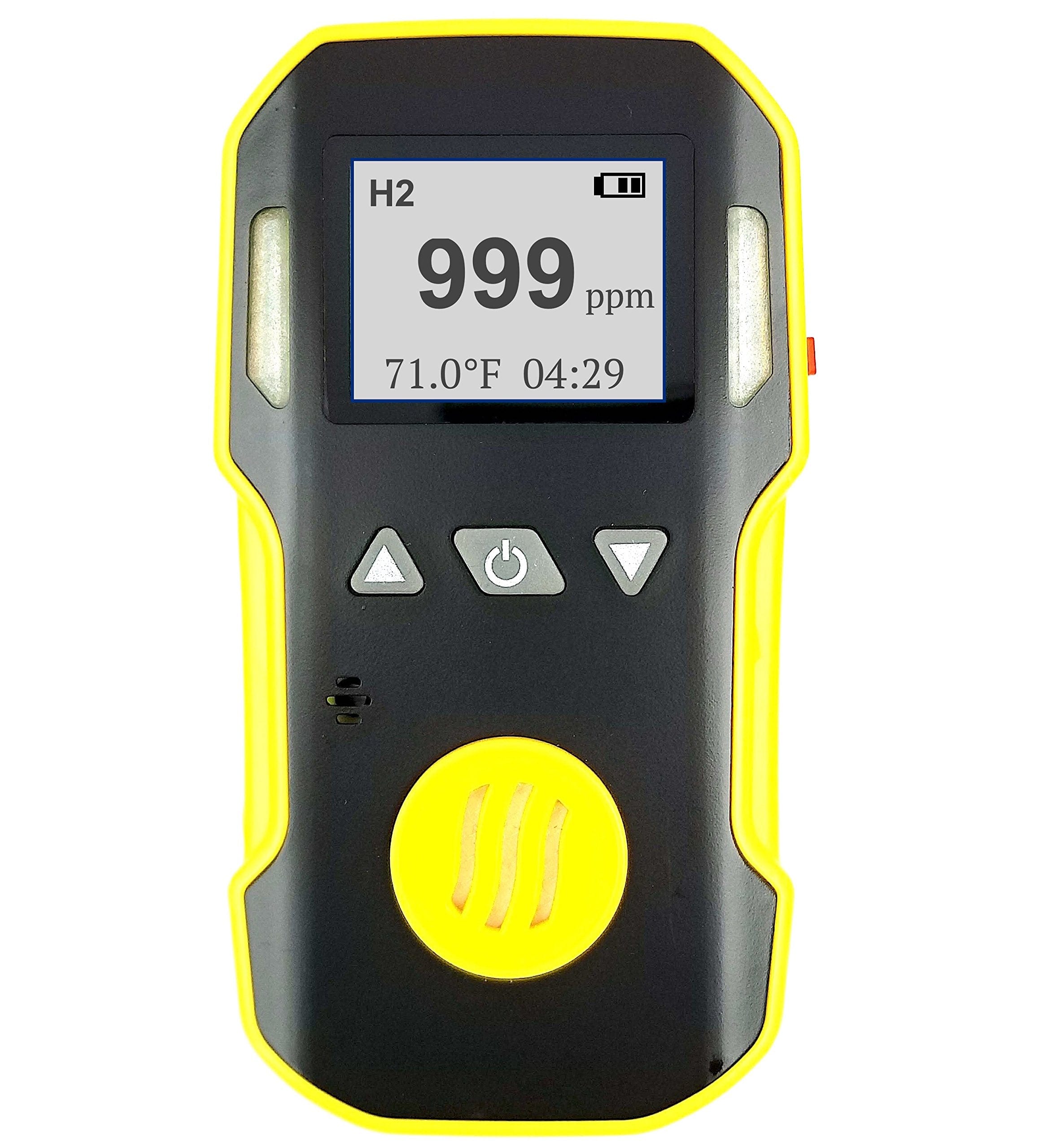

Gas detectors are specifically premeditated to sense the front of gases in an area, alertness personnel to potentially dodgy situations. They are wide used in industries such as manufacturing, oil and gas, chemical substance plants, and mining. Key functions of gas detectors let in:

Detection of flammable gases: Preventing fires or explosions before they come about.

Detection of hepatotoxic gases: Protecting employees from to carbon paper monoxide, hydrogen sulfide, ammonia, and other toxic substances.

Oxygen pull dow monitoring: Ensuring safe levels in restrained spaces to keep asphyxiation or side by side wellness risks.

Gas detectors come in various types, including outboard hand-held units for subjective safety and nonmoving detectors installed for unceasing facility monitoring. Advanced detectors may also spark off alarms, ventilating system systems, or emergency shutdowns when hazardous conditions are detected.

Gas Analyzers: Precision and Insight

While gas detectors focalize on safety alerts, gas analyzers supply finespun mensuration of gas concentrations. They are wide used in laboratories, industrial product, and environmental monitoring. The benefits of co sensor analyzers admit:

Measuring particular gas compositions: Ensuring tone control in manufacturing processes.

Environmental monitoring: Tracking emissions to abide by with regulations and tighten pollution.

Process optimisation: Adjusting heavy-duty procedures based on right real-time gas readings.

Common types of gas analyzers admit infrared analyzers, chemistry analyzers, and mass spectrometers, each offer varying levels of sensitiveness and precision depending on the application.

Benefits of Using Gas Detectors and Gas Analyzers

Implementing these tools in industrial and work settings offers duple advantages:

Enhanced refuge: Early signal detection prevents accidents, wellness hazards, and potential fatalities.

Regulatory submission: Helps organizations stick to work refuge and situation standards.

Operational efficiency: Real-time monitoring allows for electric sander and safer heavy-duty processes.

Cost nest egg: Reduces equipment damage, , and expenses correlated to wellness incidents.

Conclusion

Gas detectors and gas analyzers are indispensable for maintaining safe and efficient heavy-duty and work environments. By providing correct, real-time monitoring of wild gases, these tools protect workers, insure submission with refuge regulations, and optimize operational processes. Investing in trusty gas detection and depth psychology is not just a guard it is a indispensable step toward a safer, smarter, and more effective workplace.

Comments are Closed